Concrete is a foundational material in the construction industry, and in large-scale projects, its standard, quality, and quantity are of utmost importance. It forms the very infrastructure where we live, work, and innovate. Many projects predominantly opt for ready-mix concrete (RMC) due to its reliability and consistency. In this blog, we will explore what an RMC plant is and why it plays a crucial role in modern construction. Also we will see the best RMC plant in Ahmedabad.

Ready-mix concrete is a type of concrete that is manufactured in a batching plant (RMC plant) based on specific mix designs and then delivered to the construction site in a ready-to-use state.

What is an RMC Plant?

An RMC plant is a facility where concrete is produced in a controlled environment using precise proportions of cement, sand, aggregates, and water. The material mixture is prepared according to the design provided by the client’s engineer, which is also approved by the structural designer of the proposed building.

Also read,

AAC Blocks: A Comprehensive Guide to Benefits, and Sizes.

The Slump Test of Concrete for workability of concrete : A practical Procedures.

Why do we use PCC (plain cement concrete) in construction? 7 tips to know.

What is the meaning of RMC?

RMC stands for the Ready Mix Concrete, is a type of concrete that is manufactured in a batching plant or factory under controlled conditions. It is prepared by mixing specific proportions of cement, aggregates (sand, gravel, or crushed stone), water, and additives as per the design mix provided by the client or structural engineer. The concrete is then transported to the construction site in transit mixers(TM) in a ready-to-use state.

RMC ensures consistent quality, accurate mixing ratios, and efficient delivery, making it a preferred choice for large-scale construction projects like residential buildings, commercial complexes, roads, bridges, and infrastructure projects.

How to Choose an RMC Plant for Your Project?

As engineers, it is our responsibility to evaluate every aspect of Ready Mix Concrete (RMC) thoroughly. Before finalizing an RMC plant for your project, you should personally visit the plant, interact with their team, and consult other site engineers who have experience with various RMC suppliers. Their insights on service, quality, and reliability can be invaluable.

How to calculate the concrete quantity for the footing?

Selecting the right RMC plant isn’t a simple decision — but by keeping certain key factors in mind, you can make an informed choice. Here are the important criteria to consider:

- Concrete Quality : Ensure the mix design meets your project’s structural requirements and complies with IS codes.

- Skilled Staff : The plant should have experienced personnel, especially quality control engineers and supervisors.

- Service & Timeliness : Timely delivery, prompt response, and consistency are crucial.

- Testing Facilities : On-site labs with calibrated equipment for testing slump, compressive strength, etc.

- Customer Support : The team should be approachable and capable of resolving issues quickly.

- Distance from Site : The shorter the distance, the better the concrete retains its quality during transit.

- Record Keeping & Reporting : Proper documentation of mix designs, batch records, and test results should be maintained.

- Maintenance of Machinery : Well-maintained mixers, batching systems, and transit mixers ensure uninterrupted service.

- Safety Standards : The plant must follow all safety regulations for both workers and materials.

- Transparency : The RMC provider should be open to third-party testing and client inspections.

By checking these factors carefully, you can choose an RMC plant that not only supplies high-quality concrete but also becomes a reliable partner in your construction journey.

My experience at RMC Ramesth :

Because I have personally checked everything, and I will talk about all those things in this blog — from visiting the RMC plant, testing the material, checking the quantity and quality of all materials, inspecting the equipment used and available for testing different materials, to finalizing the ready mix concrete with Ramesth — and why I’m saying that it’s the best RMC plant in Ahmedabad.

First, I met their managing team and visited their RMC plant site. During the visit, I interacted with the quality control team, dispatch department and material testing laboratory, and also had a meeting with the managing director’s team. After personally inspecting the plant, we thoroughly checked all the essential materials used in concrete production — including cement, sand, fine aggregates, and coarse aggregates.

We ensured that each material met the required standards in terms of quality and consistency. The facility was well-organized, and the staff was cooperative in explaining their process and showing their testing setups. This initial visit helped us build confidence in the quality assurance processes followed by the plant.

Design finalization and Sample :

Following the finalization of the mix design, we visited the RMC plant located near Lavarpur, close to GIFT City in Ahmedabad, Gujarat. We handed over the approved mix design — which included different grades of concrete — to the quality engineer at the plant.

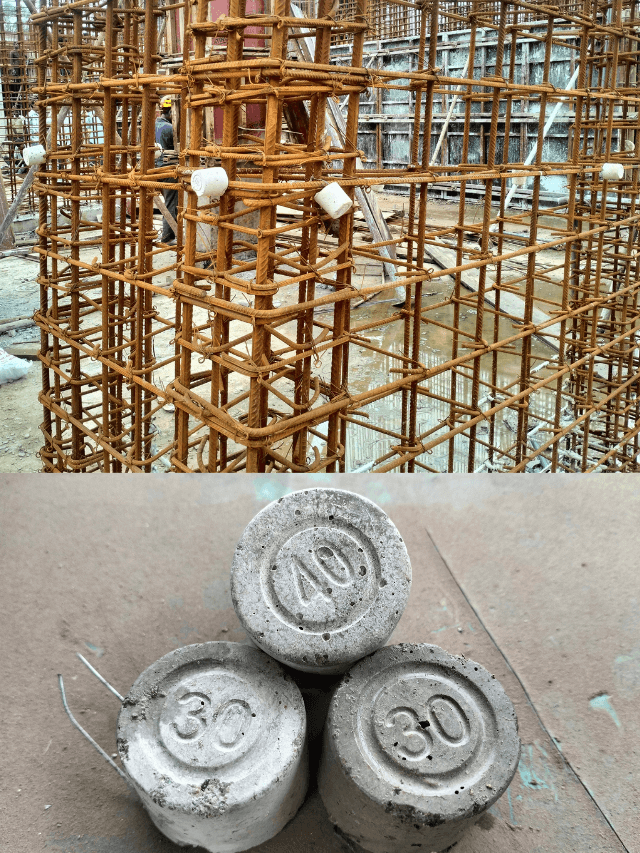

Next, we checked all the raw materials thoroughly. Each material was weighed with a precision of up to 1.0-5.0 grams to ensure exact proportions. The materials were then carefully mixed in a baby mixer under my direct supervision, strictly following the procedures laid out in the Indian Standard (IS) codes for concrete mixing.

Once the mixing was complete, we performed a slump test to verify the workability of the concrete. We also conducted other necessary tests to ensure quality.

What is a concrete lintel beam in house?

Concrete cubes were then cast to monitor the setting time and strength development over different periods. Since our construction site is located about 12–15 km away from the RMC plant, we accounted for the required transit time. The ready-mix concrete was transported to the site using a Transit Mixer (TM).

After cube casting, we followed standard IS procedures for sampling. Concrete cube samples were taken for 3-day, 7-day, 14-day, and 28-day compressive strength testing. These cubes were placed in a curing tank maintained under a temperature-controlled environment to ensure proper hydration and strength gain.

The Slump Test of Concrete for workability of concrete : A practical Procedures.

This entire process was conducted carefully and methodically to confirm that the concrete met the quality requirements for our project.

We collected concrete cube samples for testing at three different intervals: 7 days, 14 days, and 28 days. These cubes were placed in a curing tank maintained under a temperature-controlled environment to ensure proper curing and strength development.

Compressive strength test :

After 7 days, we revisited the RMC plant to test the compressive strength of the concrete using a Compressive Testing Machine (CTM). The results were satisfactory and aligned with the design expectations. Similarly, we carried out tests after 14 and 28 days, and the results were consistent and well within the acceptable range.

This entire process was carried out under the strict supervision and safety protocols of qualified engineers. The smooth execution of testing was made possible thanks to the cooperative and experienced quality control team and the supportive nature of the plant’s management.

Every parameter was thoroughly tested, and the results confirmed that the concrete mix was perfectly suitable for our project requirements.

Since then, we have placed over 1200+ cubic meters of ready-mix concrete at our site — and the supply from Ramesth RMC plant continues to meet our expectations in terms of quality, service, and consistency.

Why we choose Ramesth RMC plant?

If you’ve read through this entire blog, you now understand why I consider Ramesth RMC the best RMC plant in Ahmedabad.

- The team is extremely supportive and always ready to help.

- They have a strong problem-solving approach.

- Their service is prompt and reliable — no delays in taking or fulfilling orders.

- Ready-mix concrete is delivered on time through Transit Mixers (TMs).

- If any issues arise, they address them immediately and effectively.

- The quantity of concrete supplied is always not accurate but if any problem occurs they immediately take the actions.

- Slump is maintained exactly as per the requirement.

- Their quality engineer and supervisor are present during concrete pumping at site.

- In case of any quality concerns, their team is quick to visit the site and resolve it.

- Concrete cubes for testing are delivered with the first TM.

- They even open the cube molds the next day themselves.

- On every testing day (7, 14, or 28 days), they follow up to ensure the tests are conducted properly.

My journey to identify the best RMC plant began with a detailed visit to the Ramesth RMC plant, located near Laharpur, close to GIFT City in Ahmedabad, Gujarat. During this visit, I interacted with their management, met the quality and dispatch teams, and toured their material testing laboratory. This hands-on evaluation gave me confidence in the quality of their materials, the accuracy of their mix, and the professionalism of their team — all of which played a major role in selecting Ramesth RMC for our project.

Follow us on : Pinterest Facebook

Also read,

Why do we use PCC (plain cement concrete) in construction? 7 tips to know.

India’s First Vertical Lift Sea Bridge: Pamban Railway Bridge

Hi there! Would you mind if I share your blog with my facebook group? There’s a lot of folks that I think would really appreciate your content. Please let me know. Many thanks

sure and thanks for the words…