When concrete arrives on-site—or is mixed directly at the site—it’s crucial to check its workability. If the concrete is too workable, it likely contains excess water, which can weaken its strength and durability. On the other hand, if it’s not workable enough, it becomes too stiff to place properly, increasing the risk of honeycombing in the RCC structure—something that should be avoided. So, how can we ensure the concrete is in the right condition for pouring? Which test should be performed, and what are the acceptable values? In this blog, we’ll cover the slump test in detail, along with standard values required for different RCC components—whether you’re using a transit mixer, pumpable concrete, or doing manual casting.

The Slump Test of Concrete for workability of concrete : A practical Procedures.

Why do we use PCC (plain cement concrete) in construction? 7 tips to know.

How to calculate the concrete quantity for the footing?

AAC Blocks: A Comprehensive Guide to Benefits, Sizes, and Best Practices.

How To Calculate Quantity of Steel Using Unit Weight of Steel bars?

What is a Slump Test of Concrete?

If you are a civil engineer, ensuring the quality of concrete on-site is your top priority. One of the key initial field tests to assess the quality of fresh concrete is the slump test. This test evaluates the workability and consistency of the concrete, helping determine whether it has the correct water content, appropriate aggregate size, and proper mixing. By conducting this test, engineers can verify if the concrete is suitable for construction before it is placed. This test helps civil engineers, students, and site supervisors determine if the concrete is usable or not. It’s performed on almost every site.

If you are a civil engineer, ensuring the quality of concrete on-site is your top priority. One of the key initial field tests to assess the quality of fresh concrete is the slump test. This test evaluates the workability and consistency of the concrete, helping determine whether it has the correct water content, appropriate aggregate size, and proper mixing. By conducting this test, engineers can verify if the concrete is suitable for construction before it is placed. This test helps civil engineers, students, and site supervisors determine if the concrete is usable or not. It’s performed on almost every site.

When and Where is the Slump Test Used?

As we discussed above, the slump test is carried out on fresh concrete. It can be done both on-site and in the lab.

Most of the time, concrete is supplied through RMC (Ready Mix Concrete) plants. And on large-scale projects, there is often an on-site batching plant as well. So, the water content in the concrete can be properly checked.

When concrete comes from an RMC plant, this test helps us determine whether the water-cement ratio is maintained as per the mix design during transportation in the transit mixer.

If any adjustments are needed, we can identify them through this test. Also, it helps us check whether the concrete is coming out too stiff or too loose compared to the mix design provided.

- Quality control for fresh concrete delivery.

- Adjusting water content or admixtures on-site.

- Compliance with mix design specifications (IS 1199).

The Slump Test is primarily governed by IS 1199:2018 (Part 2), specifically for determining the consistency of fresh concrete.

Important Points Before Performing the Test:

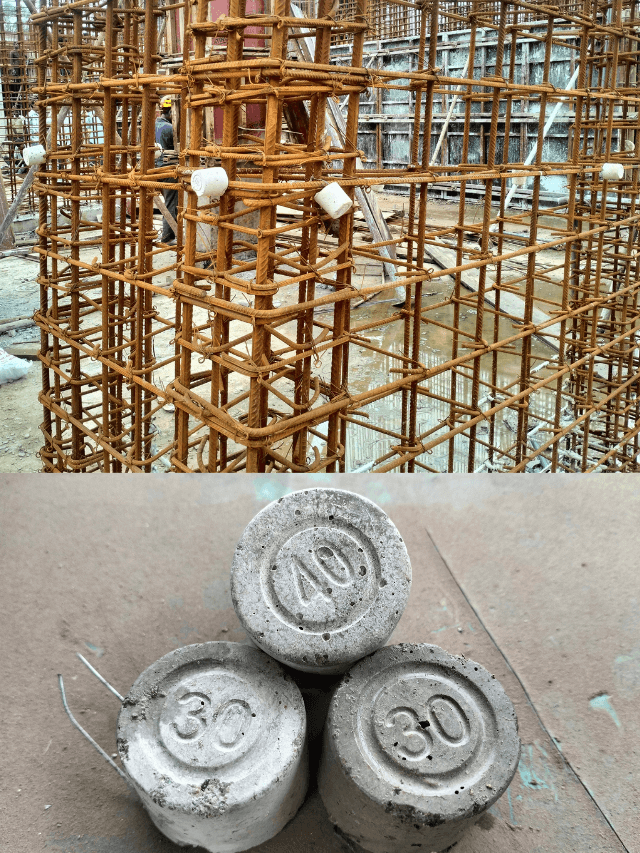

- The concrete mix should include aggregates ranging from 10 mm to 20/25/30 mm.

- It must have proper proportions of cement, fine aggregates, and coarse aggregates.

- Slump test cannot be done for dry concrete (like zero slump concrete) or concrete with aggregate size above 40 mm.

Procedure of Slump Test :

1. Apparatus Required:

- Slump cone (300 mm high, bottom diameter 200 mm, top diameter 100 mm)

- Tamping rod (16 mm diameter, 600 mm long)

- Base plate

- Measuring scale

2. Test Steps:

- Place the slump cone on a leveled base plate.

- Fill the cone with fresh concrete in three layers, each about one-third of the cone’s height.

- Compact each layer by rodding 25 times using the tamping rod. Level the top surface and carefully lift the cone vertically in 5 to 10 seconds.

- Measure the slump (difference between the original height of the cone and the settled concrete).

Types of Slump :

The type of slump is determined by observing the shape of the concrete after the slump cone is removed. Based on how the concrete settles—whether it maintains a uniform profile (true slump), shears unevenly (shear slump), or collapses entirely (collapse slump)—the workability and consistency of the mix are evaluated.

True Slump: Uniform settlement, indicating good workability.

Shear Slump: Concrete shears off on one side, indicating poor cohesion.

Collapse Slump: Concrete completely collapses, indicating excessive water.

Zero Slump: No change in shape, indicating very low workability (used for dry mixes).

Typical Slump Values (mm) :

The ideal slump range depends on the construction application. Below are general guidelines:

- Pavements / Roads: 25–50 mm

- Reinforced Beams and Slabs: 80–100 mm

- General Building Construction: 75–125 mm

- High Workability Concrete (Pumped): 100–175 mm

- General Footings: 120–130 mm

- Trapezoidal Footings: 90–100 mm

Quality Control in Construction :

Quality control (QC) ensures construction projects meet design specifications, safety standards, and durability requirements.

Workmanship Control :

- Proper curing of concrete to prevent cracking.

- Ensuring correct mixing proportions.

- Following approved construction methods and techniques.

Documentation and Reporting :

- Maintaining records of material test results.

- Regular site inspection reports.

- Regular checking and records of different slump test value for the different casting.

Also read,

How To Calculate Quantity of Steel Using Unit Weight of Steel bars?

Comprehensive Guide to the Types of Foundations in Construction.

Excavation in Construction: A Comprehensive Guide to Its Process & Types.

Introduction to Civil Engineering: What It Is and Why It Matters.

You need to take part in a contest for one of the most useful websites on the web.

I most certainly will highly recommend this blog!

Wonderful web site. A lot of useful info here. I’m sending it to several friends ans additionally sharing in delicious. And obviously, thank you on your sweat!